myndful

Darren Bennett

See it On Campus: Level 2

Visitor Info

As designers, our relationship with materials is unique. As companions on our journey, we rely on materials to bring ideas to life and create tangible products that achieve our desired outcomes. Materials offer us a vast range of possibilities, enabling us to explore new forms, textures, and colours that further enhance our designs, and it is paramount in design to understand their properties, characteristics, and even personalities to make informed decisions that result in successful creations.

It is no secret, however, that we have reached a critical junction where we recognize materials’ vital role beyond shaping our designs. We realize that our material choices also reflect deeper values, including profound environmental impacts for the future.

Therefore, we must reshape our material values, establishing new ecologically conscious pathways to guide us toward a promising and sustainable future.

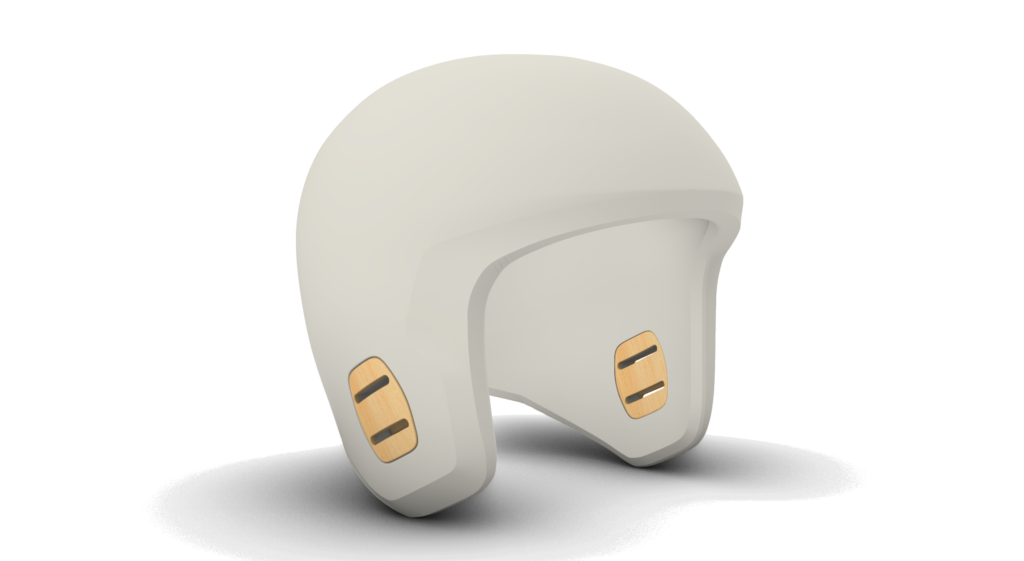

Myndful is more than a helmet grown from mycelium. It is a small step along one potential pathway toward a promising and sustainable future through its explorations of an exciting and potentially revolutionary material developing within the design industry–mycelium composites. It hopes to challenge, reshape, and inform our material choices while creating conversations that bring us closer to establishing new values for our desired future.

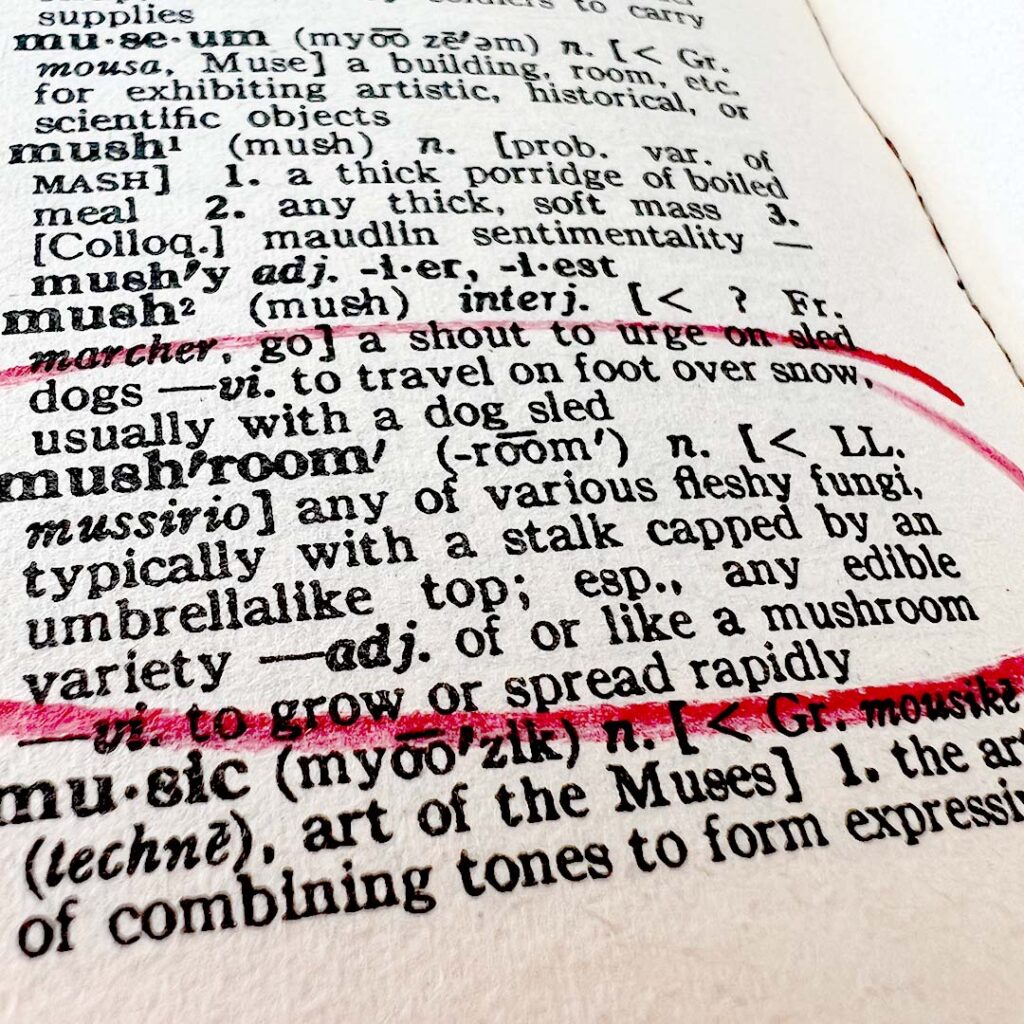

Mycelium is the vegetative root-like structure of mushrooms. It absorbs nutrients from its surrounding environments, and when conditions are suitable, it transforms into the fruiting bodies we all know as mushrooms.

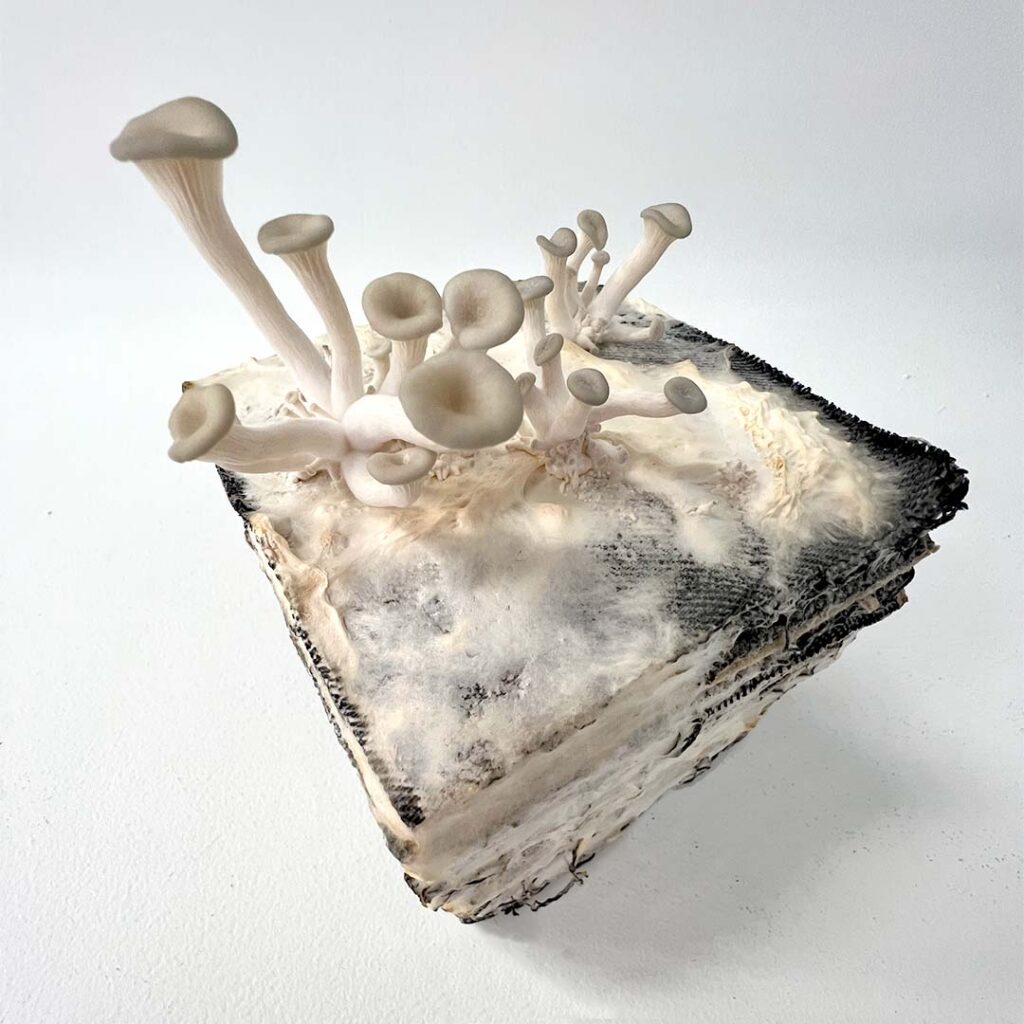

Mycelium can even absorb nutrients from books and denim, as seen in these early explorations below.

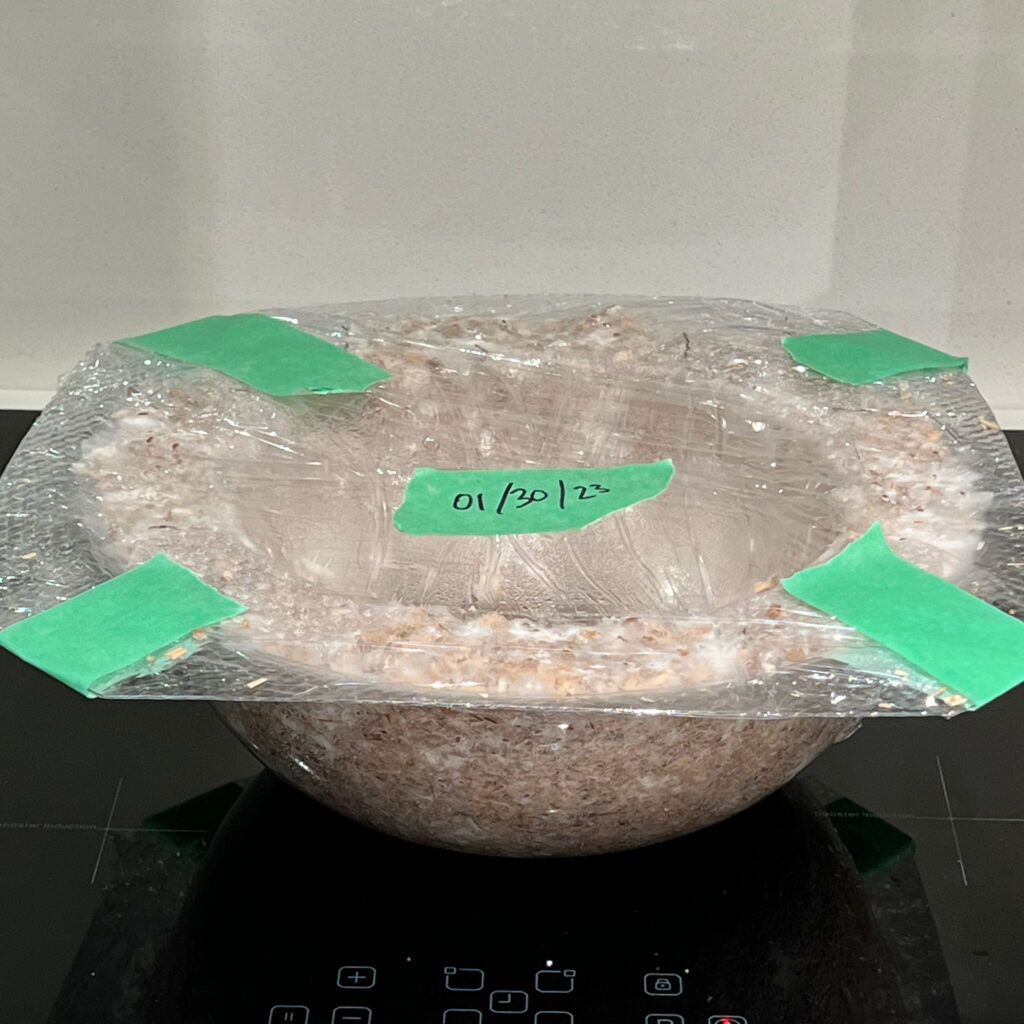

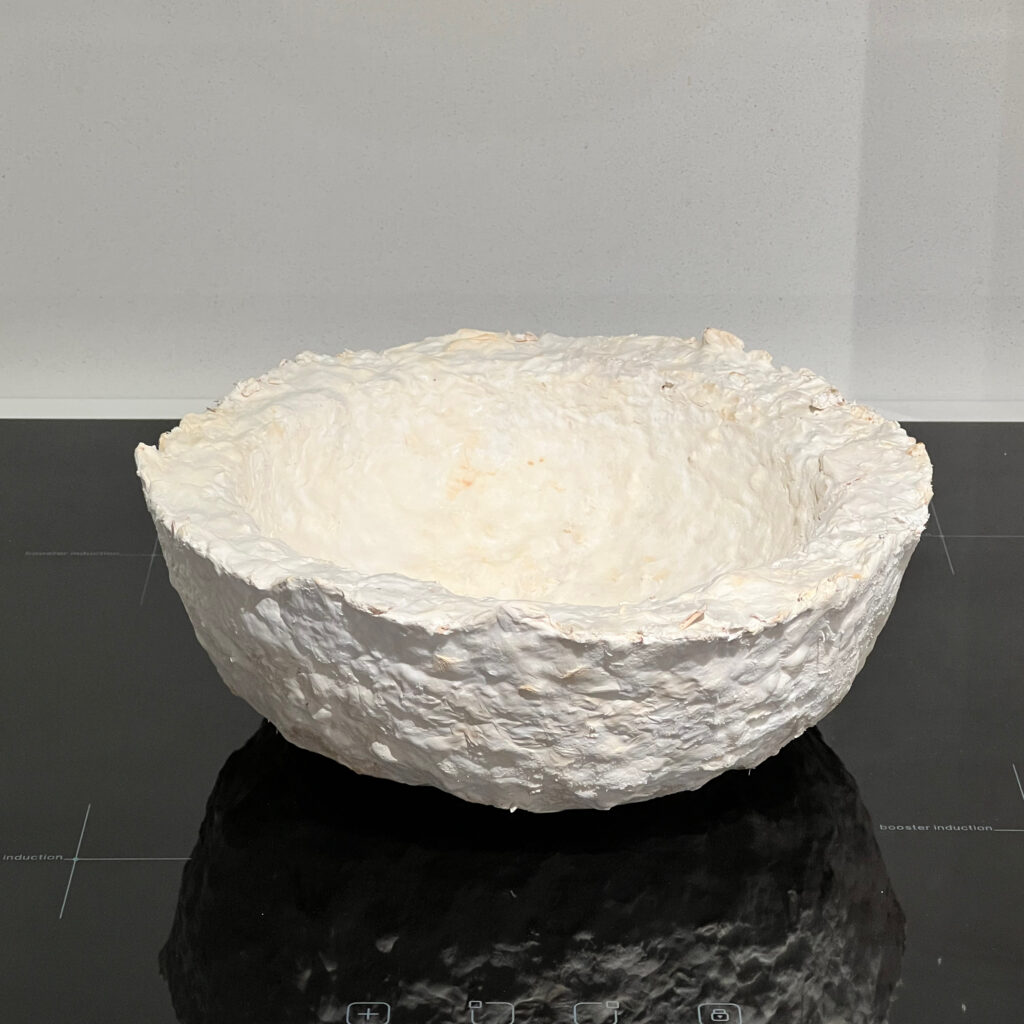

Mycelium Composites are grown with mycelium, which acts as a binding agent combining suitable nutrient-rich substrates to create versatile materials similar to expanded polystyrene. These composites are lightweight, insulative, impact and fire-resistant, and can even float. Their highly sustainable production process often utilizes discarded agricultural byproducts, helping to minimize waste and pollution. These fantastic qualities allow these composite materials to offer unique solutions that align with sustainable and eco-friendly values.

We grow mycelium composites in a mould using suitable nutritional substrates like hemp hurd and rye grain. By defining the shape of the mould, we can reshape its growth into rudimentary forms.

IS THIS A BOWL?

OR IS IT A HELMET?

Great question. How better can you reshape someone’s mind and create conversations about sustainable materials than by surrounding their head with it?

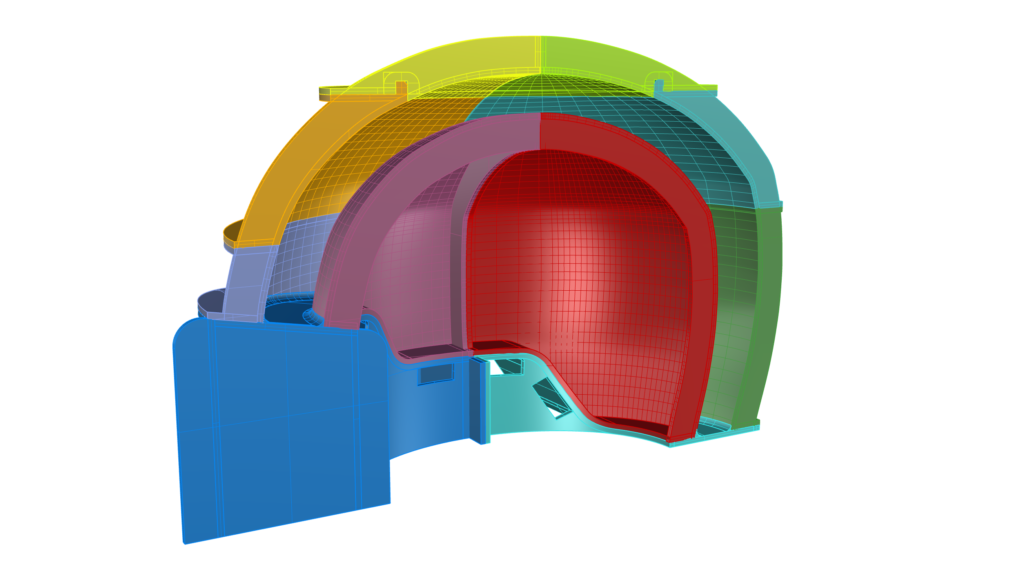

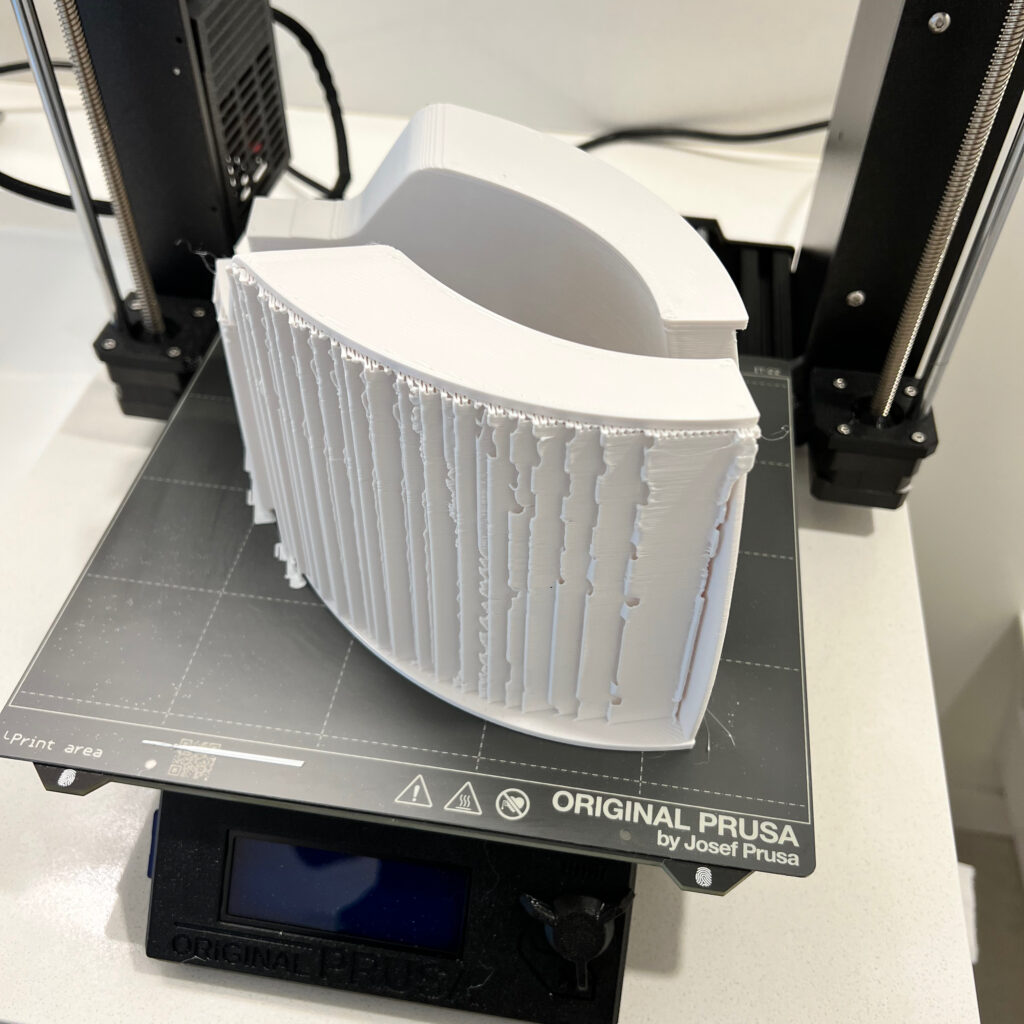

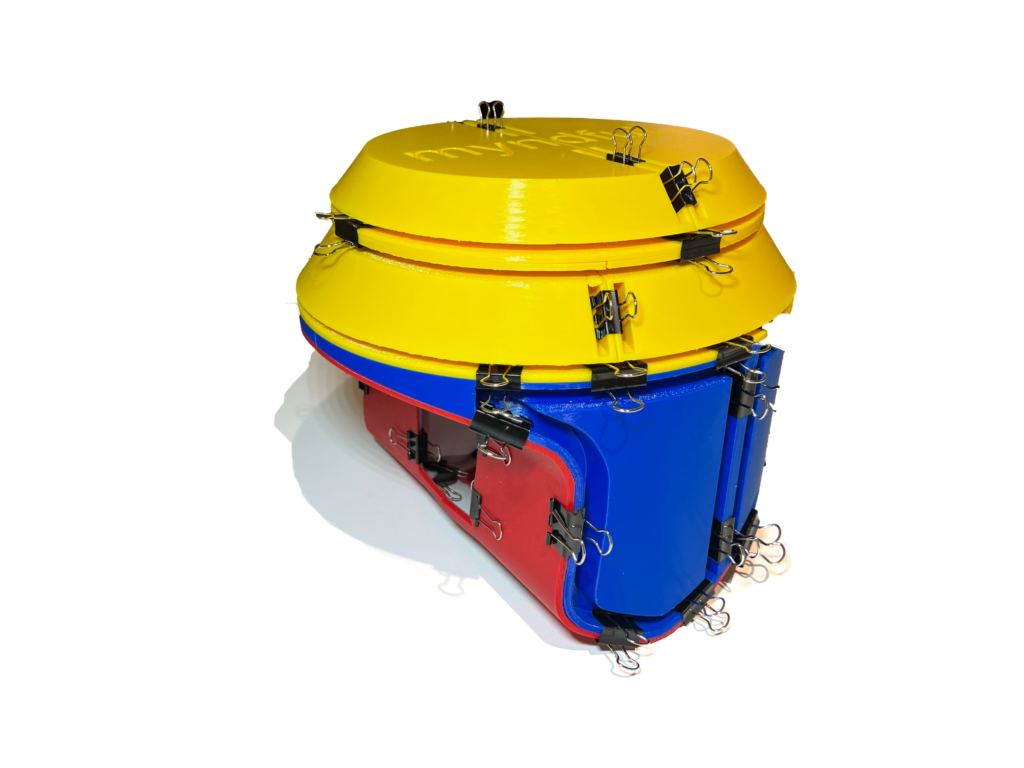

By pushing these forms further, we discover the plausibility of surrounding someone’s head with a mycelium helmet. But designing a mould more representative of a modern-day ski helmet is challenging. With all the considerations of sterilization, loading the composite mixture, undercuts and drafts, helmet straps, and, most importantly, giving mycelium the best growth environment, the complexity of the mould increases. While early explorations and iterations seemed probable, they only created more challenges. Eventually, 3D modelling a multi-piece mould that could be 3D printed provided a tangible pathway to overcoming these unique challenges.

Eventually, we get to a final helmet mould consisting of twenty-three separate 3D-printed parts. Multiple pieces allow the mould to be assembled while placing the composite mixture within it. Inversely, once the mycelium finished growing, the individual parts are easily removed from the fragile composite before it is dehydrated for strengthening.

Myndful’s journey has only just begun, and while this was only a few steps along one promising and exciting pathway, these small steps inspired tremendous conversational leaps while challenging, reshaping, and informing our material choices for a sustainable future. With a helmet in hand, we are excited to continue the work as we expand the radius of our conversations, share what we are learning, and inspire designers and others about mycelium composites’ possibilities for design and a sustainable future.